Battery Engineering

Laboratory

Battery Engineering Laboratory

Measurement of battery cell parameters including internal resistance using battery tester

Our lab conducts thorough examinations of battery cell parameters, focusing on electrical and thermal characteristics of various chemistries, mainly Lithium-Ion. We use advanced testers to improve battery performance, particularly for Electric Vehicles and energy storage systems.

Analyzing battery performance under different loads to estimate internal resistance, crucial for energy efficiency.

Comparing various battery types to optimize selection based on application needs.

Evaluating electrode and electrolyte materials to understand their impact on efficiency and lifespan.

Assessing internal resistance to gauge charging and discharging efficiency.

Measuring capacity through controlled discharge tests to predict real-world performance.

Analyzing heat generation during operation to evaluate thermal management and overheating risks.

Estimation of State of Charge (SOC) and State of Health (SOH) of Battery using MATLAB/Simulink and Experiments

In our lab, we use MATLAB/Simulink to estimate the State of Charge (SOC) and State of Health (SOH) of batteries, enabling performance monitoring and life prediction. MATLAB/Simulink is ideal for simulating battery behaviour under different conditions. Effective thermal management is essential for battery performance and safety, which we model using COMSOL Multiphysics to manage heat generation and cooling systems, ultimately enhancing battery longevity and safety.

Simulations using MATLAB/Simulink assess battery behaviour by monitoring voltage, current, and temperature to estimate State of Charge (SOC) and State of Health (SOH).

SOC is estimated via coulomb counting, voltage measurements, and impedance spectroscopy, while SOH is evaluated through internal resistance and capacity degradation.

Controlled charge/discharge cycles are conducted to validate simulation models against real-time battery performance.

Key parameters for understanding battery performance.

SOC indicates the remaining battery charge, estimated through coulomb counting and voltage-based methods.

SOH is tracked via changes in internal resistance and capacity over time, impacting voltage and current.

Assesses battery performance under various conditions.

Analyzing voltage and current profiles helps estimate internal resistance, affecting energy efficiency and heat generation.

Heat generation analysis during charge/discharge is crucial for evaluating thermal management efficiency and overheating risks.

Equivalent Circuit Modeling of Li-ion Cells via EIS Test and Temperature Chamber; Electrochemical Analysis of Li-ion Battery in Humidity Chamber.

Electrochemical Impedance Spectroscopy (EIS) is crucial for analyzing lithium-ion (Li-ion) batteries' impedance characteristics, aiding in understanding their electrical and thermal behaviour. This experiment examines the impact of humidity levels on key electrochemical parameters—charge/discharge performance, internal resistance, and cycling stability—using EIS, Cyclic Voltammetry (CV), and Galvanostatic Charge-Discharge tests in a humidity-controlled chamber.

This device measures impedance by applying a controlled AC voltage and recording the resulting current.

Explore how varying humidity levels affect the electrochemical behaviour of Li-ion batteries.

Assess the impact of moisture on charge/discharge efficiency, internal resistance, and cycling performance over time.

Offers strategies to improve battery resilience in high-humidity conditions, particularly for EVs and portable electronics.

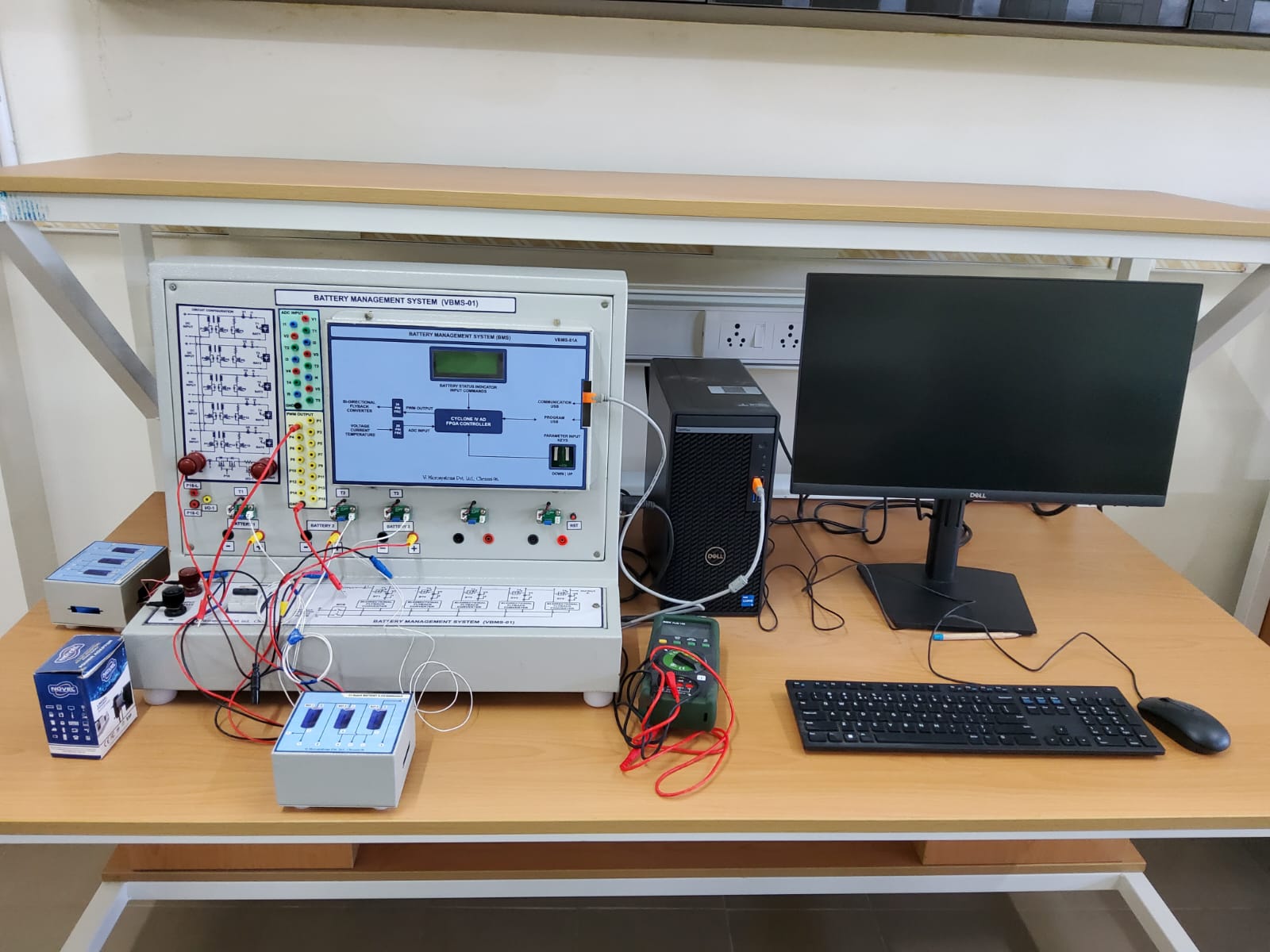

Functionality study of battery management systems

The Battery Management System (BMS) optimizes battery performance by monitoring key parameters to prevent issues.

Ensures individual cell voltages remain safe.

Tracks charge/discharge currents to prevent overcurrent risks.

Controls battery temperature to avoid overheating or freezing.

Uses algorithms to assess battery capacity and performance.

Equalizes cell voltages to prevent uneven charging or discharging.

Address

ED 505, Department of Engineering Design,

IIT Madras

Phone

044 2257 5312

lead.emobility@coezet.iitm.ac.in